Overcoming the Technical Challenges of Warehouse Management for Smooth Logistics Operations

Efficient warehouse management is the backbone of smooth logistics operations. In the fast-paced world of supply chain management, overcoming technical challenges is crucial for optimizing processes and ensuring timely deliveries.

In the dynamic landscape of logistics, a Warehouse Management System (WMS) stands as the linchpin of efficient operations. WMS is a sophisticated software solution designed to streamline and optimize every aspect of warehouse processes.

The logistics industry relies heavily on precision and speed, and that's precisely where WMS plays a pivotal role. It ensures seamless coordination, from inventory management to order fulfi llment, enhancing overall supply chain efficiency. Owing to the demands and growing importance of warehouse management systems, the global warehouse management system market is projected to witness a substantial growth from $2.8 billion in 2021 to $6.1 billion in 2026. – MarketsandMarkets.

Managing a warehouse comes with its own set of challenges. From inventory accuracy to order picking, each aspect demands careful consideration. This section delves into the complexities that warehouse managers face daily.

The Logistics Industry Landscape

The logistics industry has evolved significantly over the years, adapting to technological advancements and consumer demands. Understanding this evolution provides crucial context for the challenges and solutions explored in this article.

Modern logistics revolves around the concept of 'just-in-time' delivery, where warehouses act as strategic hubs. The efficiency of these hubs is central to meeting customer expectations and maintaining a competitive edge.

Efficient warehouse management is not merely a local concern; it has far-reaching consequences for the entire supply chain. Streamlining warehouse processes positively impacts transportation, distribution, and customer satisfaction.

Warehouse Management System (WMS) Explained

To get a clearer picture, let’s look at the key components of a WMS

Inventory Management

Accurate inventory management is the heartbeat of any successful warehouse. WMS ensures real-time tracking, minimizing errors and preventing stockouts or overstock situations.

Order Fulfillment

Timely and error-free order fulfillment is critical for customer satisfaction. WMS streamlines the entire order processing, from picking to packing and shipping.

Tracking and Visibility

WMS provides comprehensive visibility into the movement of inventory. Real-time tracking enhances decision-making and responsiveness to changing demands.

Challenges of Warehouse Management

Inventory Accuracy and Visibility

Consequences of Poor Inventory Management

Inaccurate inventory data can lead to stockouts, overstock situations, and dissatisfied customers. The financial implications are substantial, emphasizing the need for precision.

Strategies for Improving Accuracy

Implementing cycle counting, RFID technology, and regular audits are strategies to enhance inventory accuracy and maintain optimal stock levels.

Order Picking and Fulfillment Challenges

Optimizing Picking Processes

Inefficient picking processes contribute to delays and errors. Implementing zone picking, batch picking, or even advanced technologies like voice picking can significantly enhance efficiency.

Reducing Order Errors

WMS plays a crucial role in reducing order errors by automating order processing, ensuring the right products are picked and shipped with minimal manual intervention.

Space Utilization and Layout Efficiency

Maximizing Warehouse Space

Warehouse space is a valuable asset. Effective space management involves strategic layout design, vertical storage utilization, and the adoption of automation to optimize spatial constraints.

Efficient Warehouse Layout Design

A well-designed warehouse layout considers factors like product demand, storage requirements, and order picking paths to minimize travel time and maximize productivity.

Technical Challenges in Warehouse Management

Technology Adoption in Warehousing

Role of Automation

Automation, including robotic systems, enhances efficiency by handling repetitive tasks, reducing errors, and increasing throughput. Integrating automated systems with WMS is a key step in modern warehouse management.

IoT and Sensor Integration

The Internet of Things (IoT) and sensor technologies provide real-time data on various warehouse parameters, enabling proactive decision-making and enhancing overall operational visibility.

Data Security and Privacy Concerns

Safeguarding Sensitive Information

With the increasing reliance on digital systems, securing sensitive data is paramount. Encryption, secure communication protocols, and regular security audits are essential components of a robust data security strategy.

Compliance with Data Regulations

Adhering to data regulations is not just a legal requirement but also a critical aspect of maintaining trust with customers. WMS should be designed and maintained with compliance in mind.

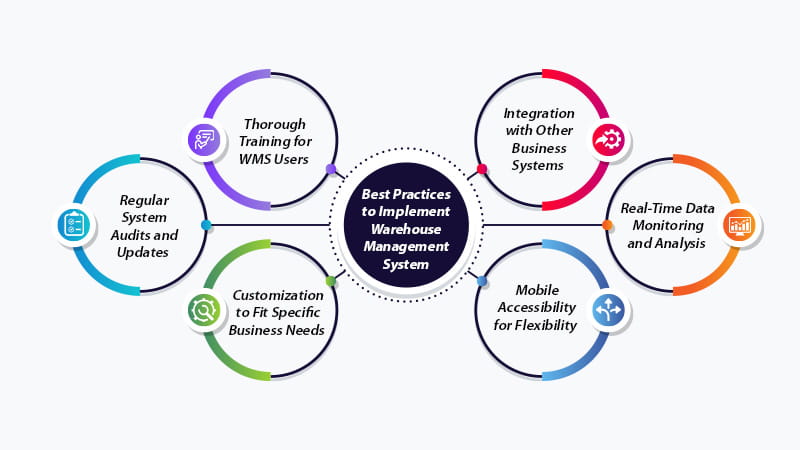

Best Practices in Warehouse Management System

Efficient warehouse management is the backbone of a smooth and effective supply chain. Implementing a Warehouse Management System (WMS) is a strategic step, and optimizing its usage requires adherence to best practices. Let’s explore key practices that can elevate warehouse operations.

Thorough Training for WMS Users

A well-implemented WMS is only as effective as the individuals using it. Provide comprehensive training for your staff to ensure they understand the functionalities of the WMS. This includes training on data entry, system navigation, and troubleshooting common issues. A well-trained team maximizes the potential of your WMS, leading to more accurate and efficient operations.

Regular System Audits and Updates

Maintaining the health of your WMS is an ongoing process. Regular system audits help identify potential issues before they escalate. Additionally, staying updated with the latest software releases and patches is crucial. This ensures that your WMS operates with optimal efficiency, incorporating new features and security enhancements.

Customization to Fit Specific Business Needs

Every warehouse has unique requirements. Customizing your WMS to align with the specific needs of your business is essential for seamless operations. Tailor the system to accommodate your inventory structure, order processing workflows, and reporting preferences. A customized WMS enhances accuracy and responsiveness to the nuances of your supply chain.

Integration with Other Business Systems

A seamless warehouse management system doesn't operate in isolation. Integrate your WMS with other business systems, such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) software. This integration ensures a cohesive flow of information across the organization, preventing data silos and streamlining overall business processes.

Real-Time Data Monitoring and Analysis

Leverage the real-time capabilities of your WMS to monitor and analyze data continuously. Real-time visibility into inventory levels, order statuses, and overall warehouse performance enables proactive decision-making. Timely insights empower your team to address issues promptly, preventing delays and optimizing operational efficiency.

Mobile Accessibility for Flexibility

In today's fast-paced business environment, flexibility is key. Ensure that your WMS is accessible via mobile devices. This mobile accessibility allows your team to manage warehouse operations on the go, improving responsiveness and reducing downtime. Whether on the warehouse floor or off-site, mobile access enhances overall operational agility.

Conclusion

Achieving a seamless warehouse management system requires a combination of thorough training, regular audits, customization, integration, real-time monitoring, mobile accessibility, and continuous improvement. By adhering to these best practices, your organization can unlock the full potential of its WMS, resulting in a more efficient and responsive supply chain.