The Future of the Logistics Supply Chain: Trends, Obstacles, and Strategies for Success

The logistics supply chain is a critical pillar of global trade and commerce, connecting manufacturers, suppliers, distributors, and customers across industries. As global markets evolve, so do the complexities within logistics. The COVID-19 pandemic brought unprecedented disruptions to supply chains worldwide, exposing vulnerabilities and driving the need for innovation. Today, companies are leveraging cutting-edge technologies such as AI, automation, and blockchain to optimize logistics operations. In this blog, we explore the latest trends, challenges, and opportunities in the logistics supply chain to help businesses stay competitive in an ever-changing market.

Key Trends Shaping the Logistics Supply Chain in 2024

As the logistics industry strives to adapt to new challenges, several key trends are influencing its transformation. These trends are reshaping logistics networks and offering businesses opportunities for growth and efficiency.

Rise of Supply Chain Visibility and Transparency

One of the most significant trends is the growing emphasis on supply chain visibility and transparency. Today’s consumers demand faster deliveries, real-time tracking, and complete transparency regarding product origin and movement. To meet these expectations, companies are leveraging technologies like the Internet of Things (IoT), advanced sensors, and cloud computing to offer real-time visibility into their supply chain.

Implementing visibility tools helps businesses reduce inefficiencies, improve decision-making, and enhance customer satisfaction by providing accurate delivery forecasts.

Automation and Robotics Revolutionizing Warehousing

Automation has become a game-changer for the logistics industry, especially in warehousing and distribution centers. The integration of robotics, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs) has streamlined inventory management, picking, packing, and shipping processes. Warehouses that adopt automation can process orders faster, reduce labor costs, and minimize human error.

By reducing manual intervention, companies can optimize space utilization and improve scalability, which is crucial as demand fluctuates.

Sustainable and Green Logistics

Sustainability has become a priority across industries, and logistics is no exception. With increasing pressure to reduce carbon footprints, companies are embracing green logistics solutions, such as electric vehicles (EVs) for transportation, energy-efficient warehouses, and optimized delivery routes. Sustainability in logistics not only enhances brand reputation but also attracts eco-conscious consumers and partners.

Moreover, regulations and policies favoring green practices are encouraging businesses to innovate and implement environmentally friendly solutions.

Blockchain for Supply Chain Integrity

Blockchain technology is emerging as a powerful tool to ensure supply chain integrity. By providing an immutable and transparent ledger of transactions, blockchain can prevent fraud, enhance traceability, and improve trust among supply chain partners. This technology is particularly beneficial for industries like pharmaceuticals and food, where product authenticity is crucial.

Blockchain also helps in streamlining documentation processes, reducing paperwork, and minimizing delays caused by traditional, manual procedures.

Last-Mile Delivery Optimization

Last-mile delivery remains a critical challenge for logistics providers due to its complexity and cost. However, companies are now investing in innovative solutions to optimize last-mile deliveries. Crowdsourced delivery models, drone deliveries, and autonomous vehicles are revolutionizing this segment, reducing costs and improving delivery times.

Efficient last-mile solutions are crucial for businesses to meet customer expectations for quick, seamless deliveries while maintaining profitability.

Challenges Faced by the Modern Logistics Supply Chain

Despite technological advancements, the logistics supply chain faces numerous challenges. These hurdles can disrupt operations and negatively impact customer satisfaction if not addressed proactively.

Global Supply Chain Disruptions

The global nature of today’s supply chains makes them vulnerable to disruptions from geopolitical tensions, natural disasters, and pandemics. Companies must develop contingency plans and diversify their supplier base to mitigate the risks of global supply chain shocks.

Furthermore, real-time risk monitoring and predictive analytics can help businesses foresee potential disruptions and respond swiftly.

High Transportation Costs

Transportation accounts for a significant portion of logistics costs, and rising fuel prices and driver shortages exacerbate this challenge. Companies are increasingly turning to alternative fuels, route optimization software, and intermodal transportation to reduce costs while maintaining service levels.

Collaborating with logistics service providers and leveraging freight pooling can also minimize transportation expenses.

Capacity Constraints and Warehousing Issues

Capacity constraints in warehousing, driven by increased e-commerce activity, are pushing logistics providers to rethink their strategies. The demand for larger, more flexible warehousing spaces is on the rise, but finding suitable locations can be challenging. Additionally, companies must balance the need for inventory management optimization with the high costs associated with warehouse expansion.

Adopting intelligent warehouse management systems (WMS) can help businesses maximize space utilization and enhance operational efficiency.

Labor Shortages in the Logistics Industry

The logistics industry is facing a significant labor shortage, particularly in roles such as truck drivers, warehouse workers, and delivery personnel. The aging workforce, coupled with a lack of skilled talent entering the field, is putting pressure on companies to fill critical roles.

To combat this, companies are investing in training programs, offering competitive wages, and implementing automation where possible to reduce dependency on manual labor.

Regulatory Compliance and Customs Complexities

With varying regulations across countries, logistics providers must navigate a complex web of customs laws, trade tariffs, and regulatory requirements. This complexity adds to operational delays and increases compliance costs. Investing in robust customs management systems and staying informed about regulatory changes can help companies remain compliant and avoid unnecessary disruptions.

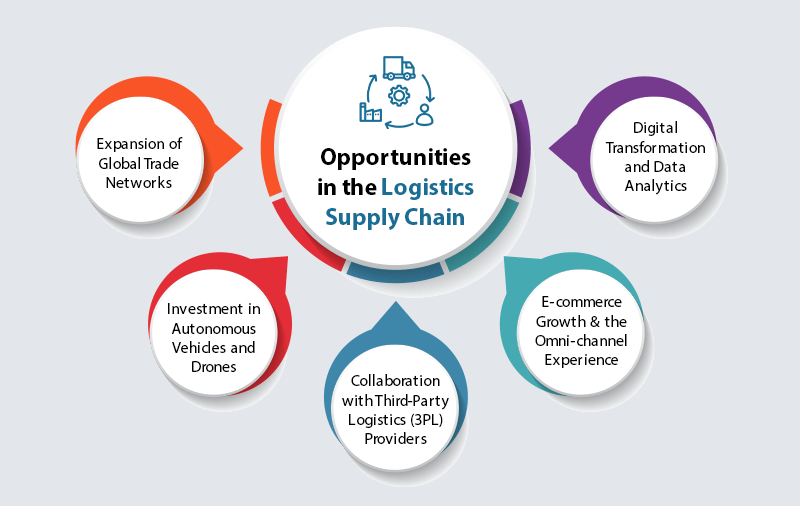

Opportunities in the Logistics Supply Chain

While the logistics industry faces its share of challenges, it also presents several growth opportunities for businesses willing to innovate and embrace new technologies.

Digital Transformation and Data Analytics

Digital transformation is unlocking significant opportunities for logistics companies. By harnessing data analytics, companies can optimize routes, forecast demand, and manage inventory more effectively. Advanced analytics tools provide businesses with actionable insights to improve decision-making and enhance overall operational efficiency.

Predictive analytics, powered by artificial intelligence (AI), is helping logistics providers anticipate demand shifts and reduce inefficiencies.

E-commerce Growth and the Omni-channel Experience

The continued growth of e-commerce is driving logistics providers to expand their capabilities. Businesses that invest in omni-channel fulfillment strategies, such as buy-online-pickup-in-store (BOPIS) or same-day delivery, can capture a larger share of the market.

To succeed, logistics companies must enhance their delivery networks, optimize their warehouse locations, and integrate technology to provide seamless customer experiences.

Collaboration with Third-Party Logistics (3PL) Providers

Partnering with third-party logistics (3PL) providers enables businesses to scale their logistics operations without investing heavily in infrastructure. 3PL providers offer expertise, technology, and resources that can help companies reduce operational costs, improve efficiency, and focus on core business activities.

By outsourcing logistics functions, companies can gain access to state-of-the-art technologies and improve their supply chain resilience.

Investment in Autonomous Vehicles and Drones

The logistics industry is witnessing increasing investment in autonomous vehicles, drones, and other advanced delivery technologies. These innovations have the potential to revolutionize delivery services by reducing labor costs, improving safety, and speeding up deliveries.

Autonomous delivery vehicles can help overcome the challenge of driver shortages while optimizing delivery routes and reducing transportation costs.

Expansion of Global Trade Networks

With international trade becoming more interconnected, logistics companies have the opportunity to expand their global networks. Businesses can explore new markets, develop strategic partnerships, and capitalize on emerging economies to grow their operations.

By investing in technology and infrastructure that supports global trade, companies can streamline cross-border logistics and enhance their competitiveness on a global scale.

Enhancing Logistics Supply Chain with Espire's Warehouse Management Solutions

Effective warehouse management is pivotal to the efficiency and success of the logistics supply chain. As e-commerce continues to surge and consumer expectations for quick, accurate deliveries rise, optimizing warehouse operations has never been more critical. Espire offers robust Warehouse Management System (WMS) solutions designed to help businesses overcome common warehousing challenges and seize new opportunities.

How WMS Solutions Optimize Warehousing

A comprehensive Warehouse Management System (WMS) addresses warehouse management challenges by automating and streamlining various warehouse processes:

- Real-Time Inventory Tracking: WMS provides accurate, real-time visibility into inventory levels, reducing the risk of errors and enhancing inventory control.

- Optimized Space Management: Advanced algorithms help in designing efficient warehouse layouts, maximizing space utilization, and facilitating easier access to goods.

- Automated Order Processing: Automation of picking, packing, and shipping processes accelerates order fulfillment and minimizes human error.

- Labor Management Tools: WMS solutions offer tools for effective workforce planning and task allocation, improving productivity and reducing labor costs.

- Data-Driven Insights: Analytics and reporting features enable businesses to make informed decisions based on operational data, identifying areas for improvement and growth.

Espire's WMS: Features and Benefits

Espire's Warehouse Management solutions are tailored to meet the dynamic needs of modern logistics operations. Key features and benefits include:

- Integration Capabilities: Seamlessly integrates with existing ERP and supply chain systems, ensuring a unified operational ecosystem.

- Scalability: Designed to grow with your business, Espire's WMS can handle increased inventory and expanded operations without compromising performance.

- User-Friendly Interface: Intuitive dashboards and user interfaces make it easy for staff to adopt and utilize the system effectively.

- Advanced Analytics: Provides comprehensive analytics and reporting tools that offer actionable insights into warehouse performance and efficiency.

- Mobile Accessibility: Supports mobile devices, enabling real-time updates and management from anywhere within the warehouse.

- Customization Options: Flexible configurations allow businesses to tailor the WMS to their specific operational requirements.

How Espire Helps Businesses Navigate Warehouse Challenges

Espire has strong partnerships with some of the leaders in warehouse management solution providers such as Blue Yonders, and leverages their expertise in WMS solutions to help businesses enhance their warehouse operations in several ways:

- Implementation Support: Espire offers end-to-end support during the WMS implementation process, ensuring a smooth transition and minimal disruption to operations.

- Training and Development: Comprehensive training programs empower warehouse staff to utilize the WMS effectively, maximizing the system's benefits.

- Continuous Optimization: < strong> Espire works with businesses to continually assess and optimize warehouse processes, ensuring sustained efficiency and growth.

- Customized Solutions: Understanding that each business has unique needs, Espire customizes its WMS to align with specific operational goals and challenges.

- Proactive Support: Ongoing technical support and maintenance services ensure that the WMS remains up-to-date and functions seamlessly.

Conclusion

The logistics supply chain is at a crossroads, with new trends, challenges, and opportunities shaping its future. Businesses that embrace digital transformation, sustainable practices, and innovative solutions like Espire's WMS will thrive in this evolving landscape. By addressing challenges such as global disruptions, high transportation costs, labor shortages, and warehouse inefficiencies, logistics providers can optimize their operations and deliver exceptional customer experiences. As the industry continues to evolve, staying ahead of trends and leveraging emerging technologies will be key to success. To lead the race of logistics business by enhancing your digital transformation journey, connect with our experts today.