The Digital Engineering Revolution: Key Aspects, Technologies, and Industry Impact | Part 1

The digital era has ushered in a transformative wave across industries, with digital engineering at its forefront. Businesses are now leveraging cutting-edge digital technologies to accelerate product development, optimize efficiency, and enhance customer experiences. This digital engineering revolution is redefining how products are designed, tested, and deployed, enabling organizations to stay competitive in an increasingly dynamic market.

From AI-driven automation to immersive augmented reality (AR) applications, digital engineering integrates advanced tools and methodologies that facilitate seamless innovation. In this blog, we explore the key aspects, technologies, and industry-wide impact of the digital engineering revolution.

Key Aspects of the Digital Engineering Revolution

Accelerated Product Development

Digital engineering enables businesses to speed up product development by leveraging rapid prototyping and iterative design processes. Traditional product development methods often involve lengthy cycles of physical prototyping and testing, which can be both time-consuming and costly. However, with digital tools such as computer-aided design (CAD), AI-driven simulations, and 3D printing, companies can create and refine prototypes faster than ever.

Furthermore, technologies like digital twins allow engineers to simulate product behavior in a virtual environment, identifying potential design flaws early in the development cycle. This reduces time-to-market, ensuring that businesses can quickly adapt to changing customer demands and technological advancements.

Enhanced Product Quality

One of the most significant advantages of digital engineering is its ability to improve product quality through virtual testing and real-time analytics. Traditional manufacturing often involves costly trial-and-error methods to identify defects. However, digital engineering leverages AI-driven simulations, digital twins, and predictive analytics to detect issues before a product reaches production.

By simulating various environmental conditions and stress factors in a virtual setting, businesses can refine product designs without expensive physical testing. Additionally, automated quality control systems powered by AI can continuously monitor production processes, reducing defects and ensuring consistency in the final product. This results in higher customer satisfaction and lower costs associated with product recalls or rework.

Optimized Efficiency

Digital engineering enhances efficiency by automating repetitive tasks, integrating real-time data analytics, and streamlining workflows. In traditional engineering environments, processes such as design approvals, material procurement, and production scheduling often involve manual coordination, leading to inefficiencies and delays.

With the adoption of AI-powered automation and cloud-based collaboration tools, businesses can minimize human errors and optimize resource allocation. For instance, predictive maintenance powered by IoT sensors can detect machinery issues before they cause downtime, preventing costly disruptions. Similarly, robotic process automation (RPA) can handle administrative tasks, allowing engineers to focus on innovation rather than routine paperwork.

Increased Sustainability

Sustainability has become a crucial factor in modern business strategies, and digital engineering plays a key role in reducing environmental impact. By integrating life cycle assessment (LCA) tools, businesses can evaluate the sustainability of their products from design to disposal.

Advanced digital simulations help engineers create products that are energy-efficient, use fewer resources, and generate less waste. For example, the aerospace industry is leveraging digital engineering to develop lightweight materials that reduce fuel consumption, while the automotive sector is designing electric and hybrid vehicles with optimized energy efficiency.

Furthermore, cloud-based digital collaboration eliminates the need for excessive physical prototypes, reducing material waste and carbon footprints. By adopting digital engineering practices, businesses can align with global ESG (Environmental, Social, and Governance) goals, attracting environmentally-conscious consumers and stakeholders.

Improved Customer Experience

In today’s customer-centric market, personalization and user experience are key differentiators. Digital engineering enables companies to tailor products and services based on real-time customer insights and preferences.

Through AI-powered data analytics and digital twin technology, businesses can analyze user behavior, predict needs, and customize offerings. For instance, automotive manufacturers use digital twins to optimize vehicle performance for individual drivers, while retail brands leverage AR/VR to offer virtual try-on experiences for online shoppers.

Additionally, real-time feedback loops powered by IoT sensors allow businesses to continuously improve products even after they reach the market. By embracing digital engineering, organizations can deliver seamless, personalized experiences that enhance customer satisfaction and brand loyalty.

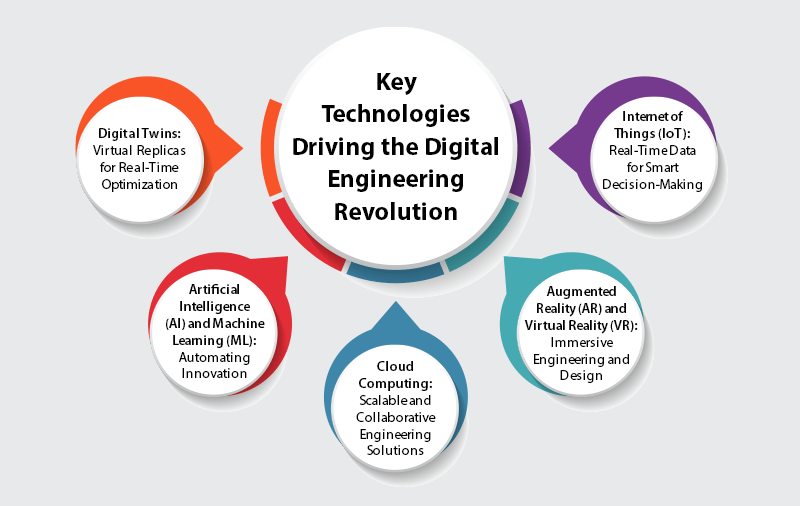

Key Technologies Driving the Digital Engineering Revolution

Digital Twins: Virtual Replicas for Real-Time Optimization

A digital twin is a virtual representation of a physical asset, system, or process that enables real-time monitoring, analysis, and optimization. This technology allows businesses to simulate real-world conditions, predict failures, and enhance performance without disrupting actual operations.

For example, in manufacturing, digital twins help optimize production lines by detecting inefficiencies before they impact output. In aerospace and automotive industries, they enable engineers to simulate aircraft or vehicle performance under different conditions, improving safety and reliability.

By integrating digital twins with AI and IoT, businesses can achieve predictive maintenance, reducing downtime and operational costs while ensuring seamless product performance.

Artificial Intelligence (AI) and Machine Learning (ML): Automating Innovation

AI and ML are at the heart of the digital engineering revolution, automating complex processes, enhancing decision-making, and optimizing workflows. These technologies allow businesses to process large datasets, identify patterns, and generate insights that drive faster and more accurate decision-making.

- AI-powered design automation accelerates product development by suggesting optimal configurations based on predefined parameters.

- Machine learning algorithms enable predictive maintenance, ensuring early detection of equipment failures in industries such as manufacturing and logistics.

- AI-driven analytics enhances customer experience by personalizing product offerings based on user behavior and preferences.

By leveraging AI and ML, companies can reduce human intervention, improve efficiency, and create smarter, self-optimizing systems that enhance overall productivity.

Cloud Computing: Scalable and Collaborative Engineering Solutions

Cloud computing provides the necessary computing power, storage, and collaborative capabilities to support large-scale digital engineering projects. Traditionally, businesses had to invest in expensive on-premise infrastructure to handle engineering simulations and data processing. However, cloud-based solutions now enable:

- Seamless collaboration among globally distributed teams, improving efficiency in design and development.

- On-demand scalability, allowing businesses to adjust computing resources based on project needs.

- Secure data storage and accessibility, ensuring engineers can work from anywhere while maintaining compliance with data security regulations.

Cloud platforms such as Microsoft Azure, AWS, and Google Cloud provide advanced AI, machine learning, and analytics services that further enhance digital engineering capabilities.

Augmented Reality (AR) and Virtual Reality (VR): Immersive Engineering and Design

AR and VR technologies are transforming product design, prototyping, and training processes by creating immersive digital experiences. These technologies enable businesses to visualize complex designs, conduct virtual simulations, and enhance remote collaboration.

- AR overlays digital information onto the physical world, enabling real-time guidance in manufacturing and maintenance.

- VR simulations allow engineers to test and refine product designs in a virtual environment before physical production, reducing material waste and costs.

- Training and skill development – Companies use AR/VR to train employees in realistic environments, improving efficiency and reducing risks in hazardous industries like aerospace and healthcare.

By incorporating AR and VR, organizations can accelerate design iterations, enhance collaboration, and improve workforce training, leading to better products and services.

Internet of Things (IoT): Real-Time Data for Smart Decision-Making

The Internet of Things (IoT) connects physical devices- such as sensors, machines, and production systems- to digital networks, enabling real-time data collection and analysis. IoT plays a crucial role in optimizing operations, predictive maintenance, and smart manufacturing.

- IoT-powered smart factories leverage sensors to monitor machine performance, detect anomalies, and automate maintenance schedules, reducing downtime.

- Supply chain optimization – Businesses use IoT data to track inventory, improve logistics, and enhance delivery efficiency.

- Customer experience enhancement – IoT-enabled devices allow businesses to personalize services based on real-time usage patterns, improving customer satisfaction.

By integrating IoT with AI and cloud computing, companies can enhance operational efficiency, reduce costs, and unlock new business opportunities.

Impact of Digital Engineering on Industries

Manufacturing: Smart Factories and Optimized Production

The manufacturing industry is one of the biggest beneficiaries of digital engineering, leveraging automation, AI-driven analytics, and IoT-powered smart factories to enhance productivity and reduce costs.

- Digital twins enable manufacturers to create virtual models of production lines, allowing real-time monitoring and optimization of workflows.

- Predictive maintenance powered by AI and IoT sensors helps prevent unexpected equipment failures, reducing downtime and maintenance costs.

- Automated robotics and AI-driven process automation improve precision in manufacturing, minimizing defects and enhancing product quality.

- Sustainable manufacturing practices – By using digital simulations, companies can design eco-friendly production methods, reducing material waste and energy consumption.

With Industry 4.0 principles driving the shift toward smart factories, manufacturers are embracing connected, intelligent systems that enhance efficiency, flexibility, and sustainability.

Automotive: Advanced Vehicle Design and Autonomous Systems

The automotive industry is undergoing a major transformation with the adoption of digital engineering in areas such as autonomous vehicles, smart mobility, and advanced vehicle simulations.

- AI-powered design simulations help engineers optimize vehicle aerodynamics, fuel efficiency, and crash safety before building physical prototypes.

- Digital twins of vehicles enable real-time monitoring of performance and predictive maintenance, ensuring reliability and longevity.

- Autonomous driving technology – AI and IoT enable self-driving cars by continuously analyzing sensor data for real-time decision-making.

- Connected vehicle ecosystems – IoT-enabled smart cars can communicate with traffic infrastructure and other vehicles to enhance road safety and navigation.

By integrating AI, IoT, and digital twins, automotive companies are developing safer, smarter, and more efficient vehicles, paving the way for the future of mobility and electrification.

Healthcare: Personalized Medicine and Advanced Medical Devices

In the healthcare sector, digital engineering is driving breakthroughs in medical research, diagnostics, and patient care, enabling personalized and data-driven treatment approaches.

- AI-powered diagnostics help doctors analyze medical images, detect diseases early, and recommend personalized treatment plans.

- Digital twins of human organs enable researchers to simulate drug interactions and treatment outcomes without human trials.

- 3D printing technology allows for customized prosthetics, implants, and medical devices, improving patient recovery and comfort.

- AR/VR in surgery – Surgeons use augmented reality to visualize complex procedures, enhancing precision and reducing risks.

By integrating AI, IoT, and digital simulations, healthcare providers can enhance patient care, reduce costs, and drive medical innovation.

Insurance: Risk Assessment and Fraud Prevention

The insurance industry is leveraging digital engineering and AI-driven analytics to improve risk assessment, fraud detection, and customer experience.

- AI-powered predictive modeling helps insurers assess risks more accurately, leading to fairer pricing and better policy management.

- Digital twins of insured assets enable real-time monitoring of buildings, vehicles, and industrial equipment, allowing insurers to offer proactive risk mitigation solutions.

- Automated claims processing – AI and machine learning streamline claims management, reducing processing time and improving efficiency.

- Fraud detection using AI – Advanced algorithms analyze patterns in claims data to identify suspicious activities, reducing financial losses.

With AI-driven automation and real-time analytics, insurers can offer more personalized services, enhance fraud prevention, and optimize risk assessment.

Logistics: Intelligent Route Optimization and Smart Warehousing

The logistics and supply chain industry is undergoing a major shift with digital engineering, AI, and IoT optimizing route planning, inventory management, and delivery efficiency.

- AI-driven route optimization helps logistics companies minimize fuel consumption and delivery times, improving overall efficiency.

- IoT-enabled smart warehouses use sensors and robotics to automate inventory tracking, reducing human errors and operational costs.

- Digital twin technology allows businesses to simulate and optimize supply chain operations, preventing bottlenecks and improving decision-making.

- Predictive maintenance for fleet management – IoT sensors track vehicle health in real-time, reducing breakdowns and improving fleet uptime.

By adopting real-time data analytics, automation, and AI, logistics companies can enhance operational efficiency, reduce costs, and improve delivery accuracy.

eCommerce: Personalization and Seamless Digital Experience

The eCommerce industry is at the forefront of digital transformation, using AI, AR/VR, and data-driven insights to create a seamless and personalized shopping experience.

- AI-powered recommendation engines analyze customer behavior to offer personalized product suggestions, increasing sales and engagement.

- Augmented Reality (AR) for virtual shopping – Customers can visualize products in real-time before purchasing, reducing return rates.

- Chatbots and AI-driven customer support provide instant assistance, improving user experience and reducing response times.

- Digital supply chain management – AI and IoT help optimize inventory, predict demand, and streamline order fulfillment.

By leveraging AI, AR/VR, and predictive analytics, eCommerce businesses can enhance customer engagement, boost conversions, and streamline operations.

Conclusion

The digital engineering revolution is reshaping industries by enhancing efficiency, improving product quality, and driving innovation. Whether in manufacturing, automotive, aerospace, healthcare, insurance, logistics, or eCommerce, businesses that leverage AI, IoT, digital twins, and cloud computing gain a competitive edge and future-proof their operations.

Ready to transform your business with digital engineering? Discover how Espire’s digital engineering solutions can help you achieve operational excellence and sustainable growth!